Expert of Slewing Bearing Manufacturer

+86 -516-8772 6238,+86 189 5222 9751

Expert of Slewing Bearing Manufacturer

+86 -516-8772 6238,+86 189 5222 9751

Fast and Safe Logistics

Get Catalogue for Free

1. Hydraulic motor is optional part, users can choose according to their own needs.

2. As there are many product models, please call us for more detailed drawings.

3. According to the needs of users professional customized processing of various non-standard slewing drive.

4. If you encounter any problems in the selection and use of the product, please contact us by email or phone.

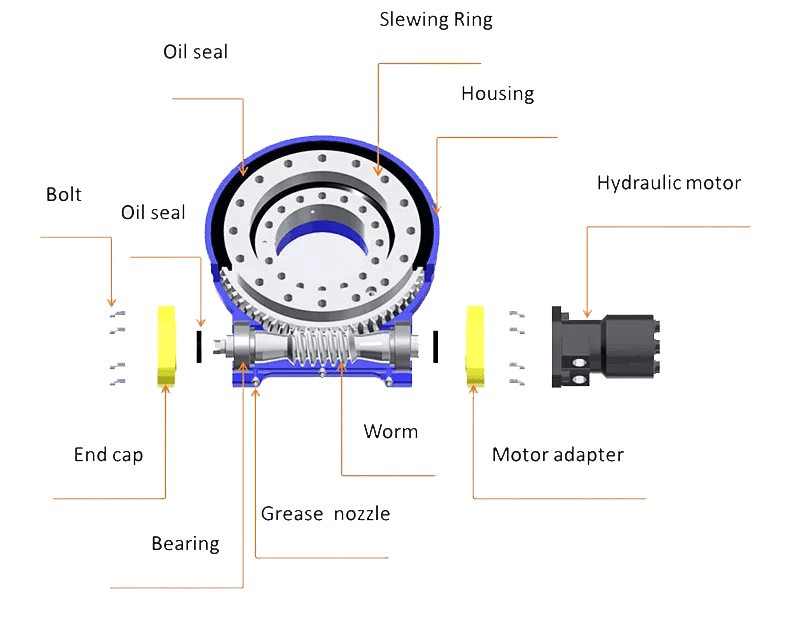

Slewing drive is a new type of slewing products, also usually called slewing bearing,it usually made of worm, slewing bearing, housing, motor and other components.

Because the core component adopts slewing bearing, it can bear axial force, radial force and overturning moment at the same time. Compared with traditional slewing products, slewing drive has the advantages of simple installation, easy maintenance and greater saving of installation space.

To provide 360-degree rotation, a hydraulic rotary device is combined with a slewing drive. We aim to understand their application, design requirements, project scope and load, and help determine the most appropriate product. We are always ready to provide technical support based on application requirements.

SE series is fenced-type slewing drive, worm gear and worm drive can realize reverse self-locking

Enclosed design make the SE Series resistant to damage from wind, rain and other harsh environments

Good solution for matching the relative rotation of two objects

WEA series is heavy duty rotary drive with high torque and maintains self-locking function.

Achieve multi-tooth meshing, better wear resistance, thinner,lighter weight

Full-sealed design can prevent corrosion and damage cause by wind, sand and water

Cranes

Solar Trackers

Wind Turbines

Utility Equipment

Automotive Lifts

Satellite Dishes

Platform Chassis Rotation

Photovoltaic Power

Hydraulic Aerial Cage

Wind Power Generation

Construction Machinery

Tire Trolley

|

Model |

External Dimensions |

Installation Dimensions |

Mounting Hole Data |

||||||||||||||

|

L1 |

L2 |

L3 |

H2 |

Do |

D2 |

D3 |

D4 |

D5 |

n1 |

M1 |

T1 |

T2 |

n2 |

M2 |

T3 |

T4 |

|

|

mm |

Inner ring |

Outer ring |

|||||||||||||||

|

SE3 |

190 |

162.5 |

80 |

109 |

152 |

100 |

|

|

100 |

6 |

M10 |

17 |

32 |

6 |

M10 |

22 |

|

|

SE5 |

219.2 |

170.5 |

93.7 |

79 |

183 |

70 |

50 |

103.5 |

135 |

7 |

M10 |

20 |

41 |

6 |

M10 |

20 |

39 |

|

SE7 |

295.7 |

186 |

132.7 |

83 |

258 |

120.6 |

98 |

163 |

203.2 |

10 |

M12 |

25 |

45 |

8 |

M12 |

25 |

43.4 |

|

SE9 |

410.5 |

321.7 |

174.2 |

107.9 |

345 |

175 |

146 |

222.5 |

270 |

15 |

M16 |

30 |

66 |

16 |

M16 |

30 |

52 |

|

SE12 |

499.5 |

339.5 |

220 |

110.4 |

431 |

259 |

229 |

314.3 |

358 |

19 |

M16 |

30 |

69 |

18 |

M16 |

30 |

51 |

|

SE14 |

529.9 |

337.5 |

237.6 |

111 |

456.5 |

295 |

265 |

342.5 |

390 |

23 |

M16 |

30 |

69 |

18 |

M16 |

30 |

52 |

|

SE17 |

621.3 |

385.2 |

282.6 |

126 |

550.5 |

365.1 |

324 |

422.1 |

479.4 |

20 |

M16 |

32 |

79 |

20 |

M16 |

32 |

55 |

|

SE21 |

751.4 |

475 |

345 |

140 |

667.7 |

466.7 |

431.8 |

525.5 |

584.2 |

35 |

M20 |

40 |

85 |

36 |

M20 |

40 |

|

|

SE25 |

863 |

469 |

401.8 |

130 |

792 |

565 |

512 |

620 |

675 |

35 |

M20 |

40 |

87 |

36 |

M20 |

40 |

|

|

Model |

Rated Output Torque KN.M |

Tilting Moment Torque |

Static Axial Load |

Static Radial Load |

Dynamic Axial Load kN |

Dynamic Radial Load kN |

Holding Torque KN.M |

Gear Ratio |

Tracking Precision |

Self-locking Gears |

Weight (KG) |

|

SE3 |

0.4 |

1.1 |

30 |

16.6 |

9.6 |

8.4 |

2 |

62:1 |

≤0.20 |

Yes |

13 |

|

SE5 |

0.6 |

3 |

45 |

22 |

14.4 |

11.1 |

5.5 |

62:1 |

≤0.20 |

Yes |

14 |

|

SE7 |

1.5 |

13.5 |

133 |

53 |

32 |

28 |

10.4 |

73:1 |

≤0.20 |

Yes |

23 |

|

SE9 |

6.5 |

33.9 |

338 |

135 |

81 |

71 |

38.7 |

61:1 |

≤0.20 |

Yes |

50 |

|

SE12 |

7.5 |

54.3 |

475 |

190 |

114 |

100 |

43 |

78:1 |

≤0.20 |

Yes |

65 |

|

SE14 |

7 |

57.8 |

555 |

222 |

133 |

117 |

48 |

85:1 |

≤0.20 |

Yes |

70 |

|

SE17 |

10 |

135.6 |

970 |

390 |

235 |

205 |

72.3 |

102:1 |

≤0.15 |

Yes |

105 |

|

SE21 |

15 |

203 |

1598 |

640 |

385 |

335 |

105.8 |

125:1 |

≤0.15 |

Yes |

180 |

|

SE25 |

18 |

271 |

2360 |

945 |

590 |

470 |

158.3 |

150:1 |

≤0.15 |

Yes |

218 |

WE series

|

Model |

External Dimensions |

Installation Dimensions |

Mounting Hole Data |

|||||||||||||

|

L1 |

L2 |

L3 |

H2 |

Do |

D2 |

D3 |

D4 |

D5 |

n1 |

M1 |

T1 |

T2 |

n2 |

M2 |

T3 |

|

|

mm |

Inner ring |

Outer ring |

||||||||||||||

|

WE9 |

424 |

330 |

180 |

108 |

360 |

175 |

146 |

222.5 |

270 |

15 |

M16 |

30 |

62 |

16 |

M16 |

30 |

|

wE12 |

509 |

370 |

222.5 |

108 |

445 |

259 |

229 |

310 |

358 |

19 |

M16 |

30 |

62 |

18 |

M16 |

30 |

|

WE14 |

544 |

380 |

240 |

108 |

480 |

295 |

265 |

342 |

390 |

23 |

M16 |

30 |

56 |

18 |

M16 |

30 |

|

WE17 |

634 |

405 |

285 |

108 |

570 |

365.1 |

332 |

430 |

479.4 |

20 |

M16 |

32 |

62 |

20 |

M16 |

32 |

|

WE21 |

762 |

483 |

350 |

130 |

693 |

466.7 |

425 |

540 |

584.2 |

35 |

M20 |

40 |

70 |

36 |

M20 |

40 |

|

WE25 |

861 |

513 |

399 |

130 |

793 |

565 |

525 |

630 |

675 |

35 |

M20 |

40 |

70 |

36 |

M20 |

40 |

|

Model |

Rated Output Torque KN.M |

Tilting Moment Torque |

Static Axial Load |

Static Radial Load |

Dynamic Axial Load kN |

Dynamic Radial Load kN |

Holding Torque KN.M |

Gear Ratio |

Output Speed RPM |

Self-locking Gears |

Weight (KG) |

|

WE9 |

8 |

33.9 |

550 |

205 |

130 |

110 |

38.7 |

61:1 |

<3 |

Yes |

53 |

|

wE12 |

9.5 |

54.3 |

725 |

270 |

180 |

140 |

43 |

79:1 |

<3 |

Yes |

66.8 |

|

WE14 |

10.8 |

67.8 |

920 |

343 |

220 |

190 |

48 |

86:1 |

<3 |

Yes |

75 |

|

WE17 |

12.96 |

135.6 |

1110 |

414 |

268 |

220 |

72.3 |

104:1 |

<2 |

Yes |

96 |

|

WE21 |

28.7 |

203 |

1595 |

596 |

340 |

270 |

105.8 |

90:1 |

<1.5 |

Yes |

172 |

|

WE25 |

34.2 |

310 |

1850 |

690 |

440 |

320 |

158.3 |

104:1 |

<1.5 |

Yes |

202 |

Error: Contact form not found.