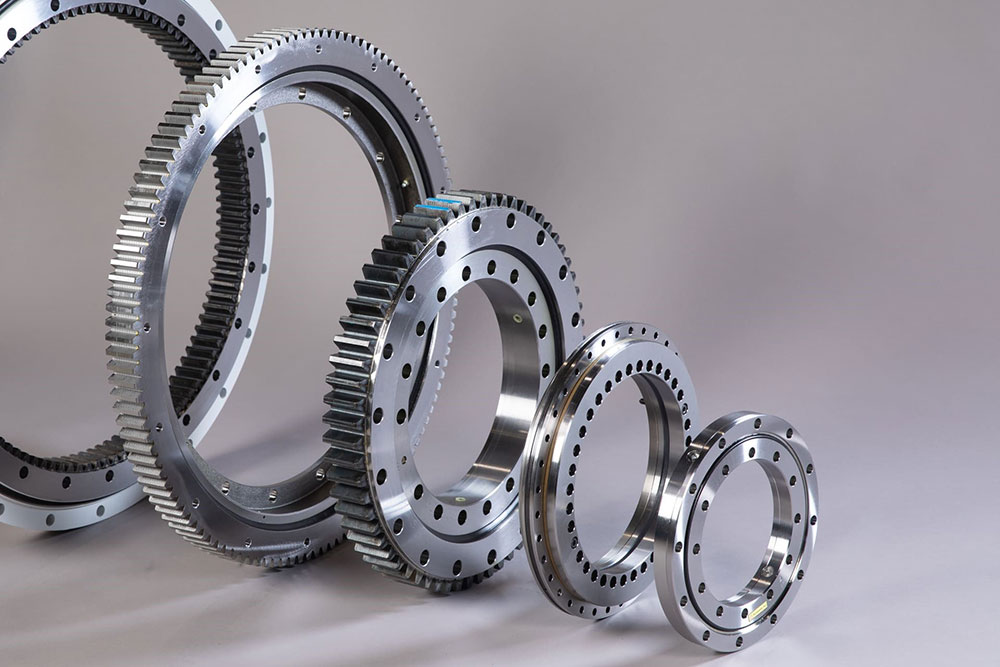

Professional Slewing Bearing Manufacturer

Since its establishment, the company has adhered to the development concept of "people-oriented and common development" and fully implemented the ISO9001 management system; The products have passed strict dynamic and static tests to ensure that all technical indicators meet the quality requirements.

-

Professionl Team

Highly skilled team and testing equipment

-

Design and R&D

We specializes in R & D, production and sales